-

PRODUCTS

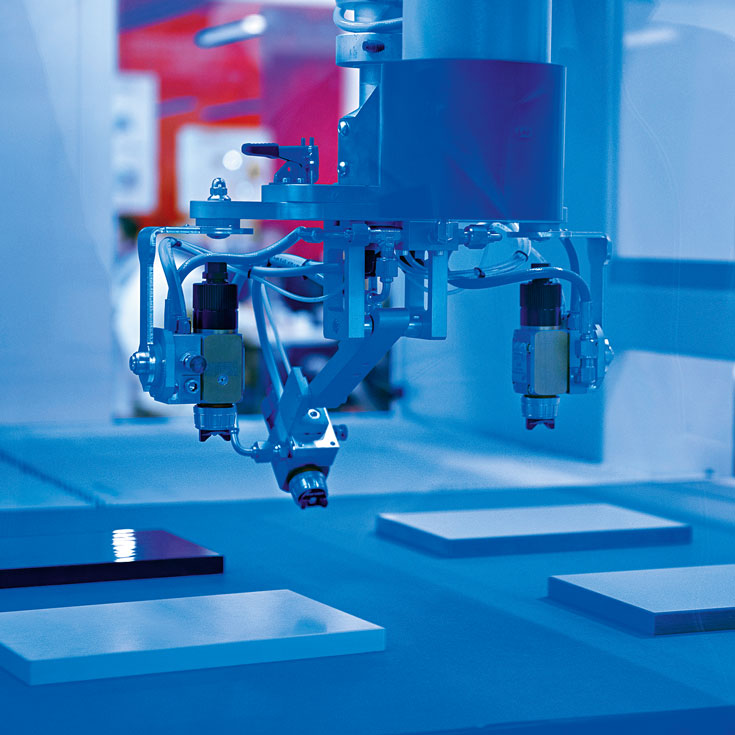

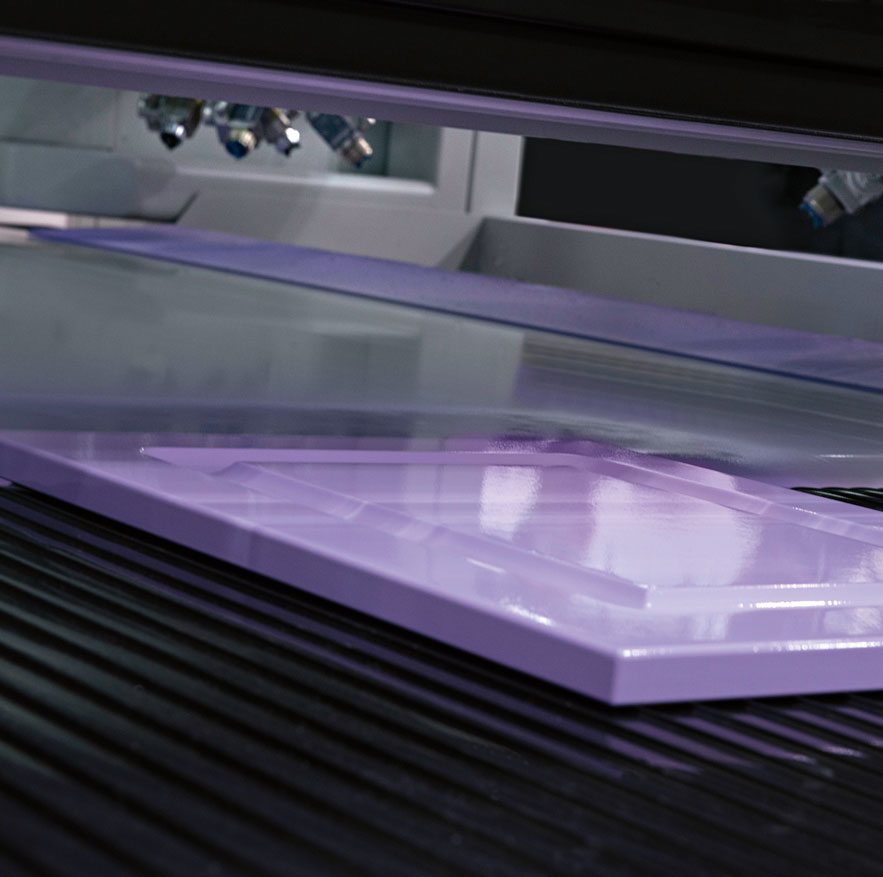

Our products are designed to protect and decorate wood and glass with a common denominator in mind: to combine innovation, high quality and low environmental impact.

Our products are designed to protect and decorate wood and glass with a common denominator in mind: to combine innovation, high quality and low environmental impact.

-

SERVICES AND CONSULTING

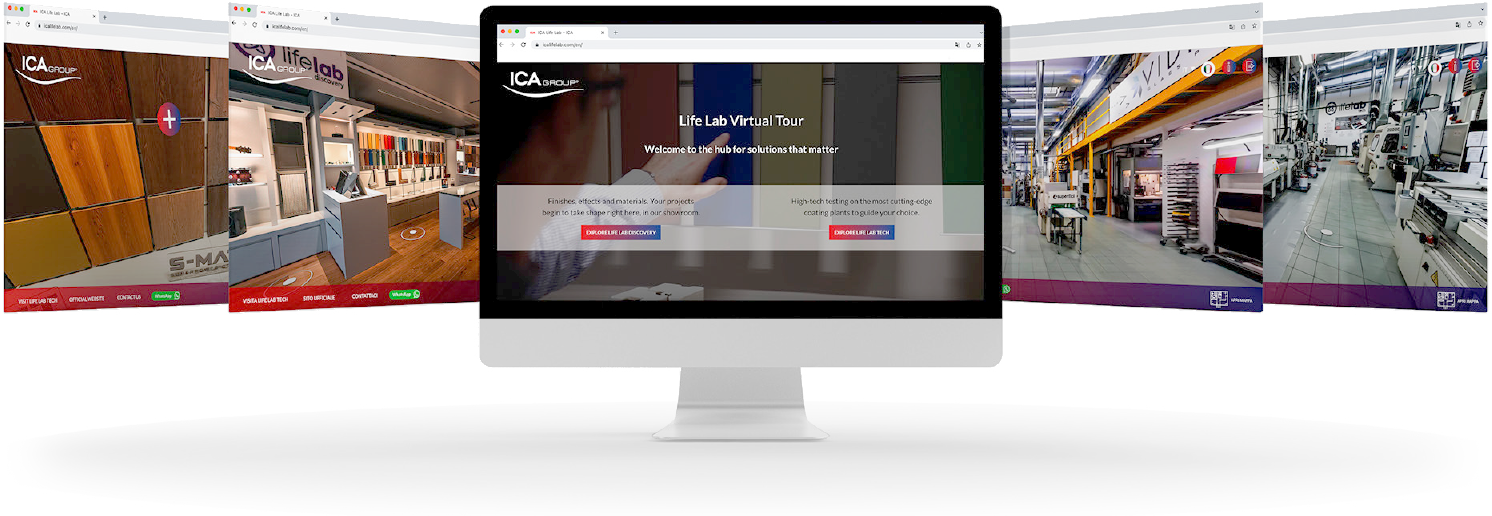

ICA INNOVATION CAMP is knowledge, relationships, and daily innovation. It is the perfect place to discover how a product is created, what drives a creative process, how a new coating is tested, and much more.

-

DESIGN & PLAN

The ICA Group world is constantly evolving, always attentive to design trends and to the requests of designers and architects. Our color and finish trends are a source of inspiration for the Italian and international market every day.

The ICA Group world is constantly evolving, always attentive to design trends and to the requests of designers and architects. Our color and finish trends are a source of inspiration for the Italian and international market every day.

- Case Study

- Sales Network

-

THE GROUP

We are a big group with firm and deep roots. Thanks to our know-how, R&D investments, respect for the environment and high quality, we have become world leaders in innovative coatings for wood and glass.

We are a big group with firm and deep roots. Thanks to our know-how, R&D investments, respect for the environment and high quality, we have become world leaders in innovative coatings for wood and glass.

- News