We have provided our water-based coatings and consulting for this innovative and sustainable project.

Ossicolor, a company that is always moving forwards

A company pursuing growth must innovate and this case study explores how. Ossicolor, a company specialized in processing aluminum components for use in the furniture industry, has decided to take an important step towards sustainability with a new highly automated coating system. We have played a central role in this project with our water-based coatings.

Ossicolor was established in Trento in 1971, through the determination of founders Matteo Cecchele and Luigi Masciocchi. Since 1971, it has never ceased to grow. The company is now highly advanced, specializing in mechanical processing and treatment of extruded aluminum, and its products are distributed in various countries, including the UK, Germany, France, Austria and Spain.

In addition to determination, this growth is driven by a great desire to innovate in the sector, seeking new solutions to improve products and make processes more sustainable. To achieve this, Ossicolor has often ventured into unexplored territory, including its choice to create an in-house coating system using water-based products.

ICA Group and Ossicolor technical personnel working together for growth

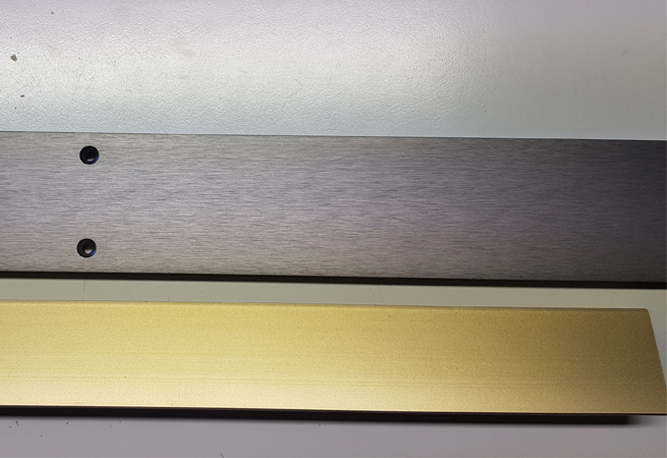

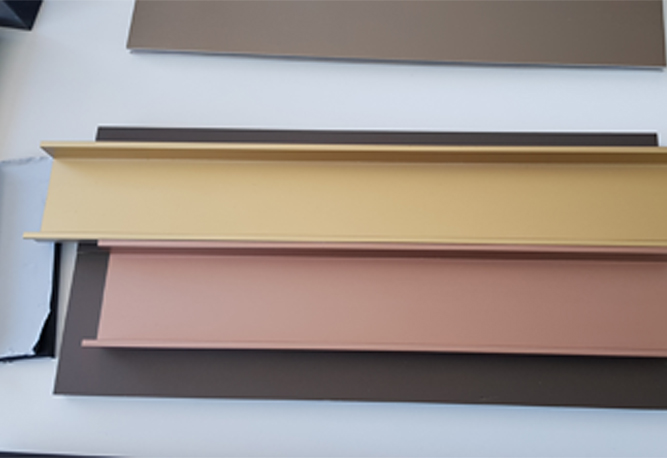

With the experience gained in management of its in-house oxidization system, Ossicolor began a new adventure. This time, its aim was to create an automated system dedicated to coating its products, integrating coatings with a low environmental impact and outstanding aesthetic results, superior even to those achieved with powder and electrochemical coating.

It was an ambitious goal. For its achievement, the company gathered a team of experts, including a systems designer, building designer, environmental consultant, and our Research and Development laboratories and Performance Lab, as well as our technical assistance personnel who, in addition to identifying the best product for the customer, also helped the team to set up a system that optimizes the coating process.

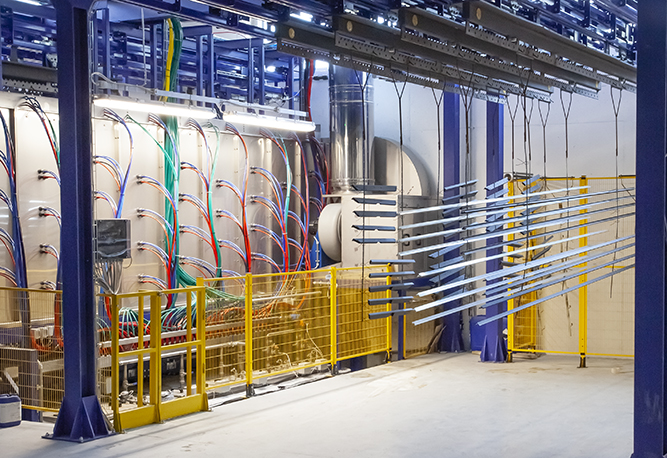

The result is this large-scale new automated machine that uses our water-based coatings.

“Involving the ICA Group R&D laboratory right from the system design phase enabled us to define the capacity of flash-off and curing ovens based on the characteristics of coatings proposed, and to identify the best application methods, installing an automatic mixing system with electrostatic application for water-based products. Our personnel were thus already trained before the system was operational and our sales team were able to show customers the new finishes created on our aluminum profiles (handles and furnishing accessories). Our goal was comprehensively achieved, as we are testing all of the effects we create through the accredited Performance Lab, and obtaining outstanding results for chemical-physical resistance.” These were the comments of Ossicolor’s owner, Roberto Masciocchi.

We will simply add that it has given us great satisfaction to accompany this project right from the starting phases, offering our consulting and our products, and finally seeing the system in operation.

Our products are designed to protect and decorate wood and glass with a common denominator in mind: to combine innovation, high quality and low environmental impact.

Our products are designed to protect and decorate wood and glass with a common denominator in mind: to combine innovation, high quality and low environmental impact.

The ICA Group world is constantly evolving, always attentive to design trends and to the requests of designers and architects. Our color and finish trends are a source of inspiration for the Italian and international market every day.

The ICA Group world is constantly evolving, always attentive to design trends and to the requests of designers and architects. Our color and finish trends are a source of inspiration for the Italian and international market every day.

We are a big group with firm and deep roots. Thanks to our know-how, R&D investments, respect for the environment and high quality, we have become world leaders in innovative coatings for wood and glass.

We are a big group with firm and deep roots. Thanks to our know-how, R&D investments, respect for the environment and high quality, we have become world leaders in innovative coatings for wood and glass.